- Home

- Online Factory

- Production Equipment

Production Equipment

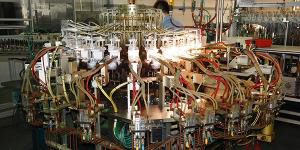

The integrated full automatic imported production line is used to produce H7 headlight bulb. Fully automated, this line reduces errors caused by manual operation and thus ensures the consistency of product quality. The bulb's core component, filament, is automatically welded and installed by a robot hand. The precision and efficient production ensures that the finished product meets relevant standards and improves driving safety at night.

Our H4 headlight bulb is automatically assembled by machine, so its overall performance can be highly guaranteed. The high temperature cap coating machine is used to coat the bulb cap with a layer of shading material, so as to block certain light beams to create dual function illumination within one lamp. The shading layer coated by our high temperature cap coating machine will not peel off or blister when the bulb works. This cap coating technology has won national patent in 2011.

Our H4 hard glass tube drawing equipment is the most advanced in the domestic industry. Unlike traditional glass tube making technology that may leave the finished tube with internal stress, the glass tube drawing technology preserves the integrity of the glass tube through the process of heating and drawing, leaving a sleek tube that does not easily leak or break.

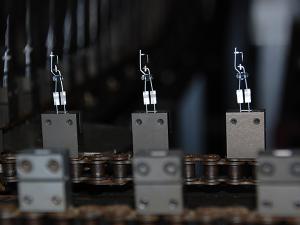

The filament is the heart of a light bulb. We use high precision automatic filament winding equipment which can automatically wind filament according to the preset dimension values, thus ensuring filament quality consistency and bulb performance.

Our research personnel have explored and made achievements in raw material selection, light shape design, lamp heat dissipation, and other aspects about LED lamp, making our LED auto lamp gradually occupy the market. Our antistatic workshop is equipped with efficient LED production line as well as testing equipment. Since LED light source is small in size, the layout within the lamp is freer, thus reducing the overall size of the LED headlight.

Our LED auto lamp responds fast. The color temperature of the light it emits exceeds 5,000K which is close to that of sunlight, thus making driving safer. In addition, as LED generates low heat, there is little change in temperature inside the lamp. Therefore, the lamp inner wall is not easily misted.

The crystal lamp is mainly used in large trucks and long-distance trucks. Traditional crystal lamp adopts filament structure and is filled with gas. But this process is complicated and the lamp has short life span. After researching and experimenting, we introduced new generation xenon sealed beam lamp which use a special halogen bulb as the light source instead of merely filament. This simplifies production and assembly while improving the performance and service life of the lamp.

The car headlight is demanding on the shape of the light emitted by the headlight bulb while the formation of light shape depends on the focusing ability of the bulb. Our company uses auto focus welding machine to automatically identify the luminous center position of the bulb, thus making each bulb emits light with shape meeting relevant requirement.